Geomembranes, particularly high-density polyethylene (HDPE) geomembranes, play a crucial role in various engineering applications. These materials have gained prominence in the construction and environmental sectors due to their remarkable properties and versatility. In this article, we will explore the working principles of geomembranes, particularly HDPE geomembranes, and discuss their significance in engineering projects.

I.Understanding Geomembranes

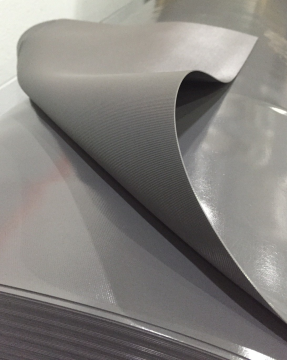

Geomembranes are impermeable membranes used in civil engineering, environmental protection, and water management. They are typically made from synthetic materials, with HDPE geomembranes being one of the most widely used types due to their high resistance to chemical attack, UV radiation, and environmental stressors. Their unique composition makes them ideal for applications requiring effective containment and separation.

II.Working Principle of Geomembranes

The primary function of a geomembrane is to provide a barrier that prevents the movement of fluids and gases. This impermeability is achieved through the material’s molecular structure, which forms a dense network that restricts the passage of water and other substances. The effectiveness of a geomembrane depends on several factors, including material thickness, manufacturing quality, and installation techniques.

Permeability

Permeability refers to the ability of a material to allow fluids to pass through it. Geomembranes are designed to be highly impermeable, which means they prevent the flow of liquids and gases. HDPE geomembranes, in particular, exhibit exceptionally low permeability, making them suitable for applications such as landfill liners, containment ponds, and wastewater treatment facilities.

Chemical Resistance

HDPE geomembranes are known for their excellent chemical resistance. They can withstand exposure to a wide range of chemicals, including acids, bases, and solvents, making them suitable for industrial applications. This chemical resistance ensures that the integrity of the geomembrane remains intact even in harsh environments, thereby enhancing its effectiveness as a barrier.

Durability and Longevity

The durability of geomembranes is a significant factor in their performance. HDPE geomembranes possess high tensile strength and resistance to punctures, tears, and abrasions. This durability allows them to withstand the mechanical stresses encountered during installation and throughout their service life. Properly installed geomembranes can last for decades, making them a cost-effective solution for engineering projects.

III.Applications of Geomembranes in Engineering

Geomembranes find application in various engineering projects, particularly in areas where fluid containment and environmental protection are critical. Here are some of the key applications:

Landfill Liners

One of the most common uses of HDPE geomembranes is as liners for landfills. These geomembranes act as barriers, preventing leachate—a potentially harmful liquid formed from the decomposition of waste—from contaminating the surrounding soil and groundwater. By using geomembranes, landfill operators can ensure compliance with environmental regulations and protect public health.

Containment Ponds

HDPE geomembranes are also extensively used in the construction of containment ponds. These ponds are essential for storing hazardous materials, such as chemicals and wastewater, without risking leakage into the environment. The impermeability of geomembranes ensures that the contents of the ponds remain contained, thereby minimizing environmental impact.

Water Management

In water management systems, geomembranes serve multiple purposes. They can be used to line reservoirs, preventing water loss due to seepage. Additionally, they can help control sedimentation in water bodies and provide a barrier against contamination from surrounding soils. The use of HDPE geomembranes in these applications enhances the efficiency and sustainability of water resources.

Soil Erosion Control

Geomembranes also play a significant role in soil erosion control. When used in conjunction with other erosion control measures, such as vegetation and soil stabilization techniques, geomembranes can help reduce soil erosion caused by water runoff. They create a physical barrier that protects the underlying soil and vegetation, promoting sustainable land management practices.

Mining Operations

In the mining industry, HDPE geomembranes are utilized for various purposes, including heap leach pads and tailings storage facilities. These applications require robust containment solutions to manage hazardous materials and prevent contamination of surrounding ecosystems. The chemical resistance and durability of geomembranes make them an ideal choice for such demanding environments.

Conclusion

Geomembranes, particularly HDPE geomembranes, are essential materials in modern engineering. Their unique properties, including impermeability, chemical resistance, and durability, enable them to perform effectively in a wide range of applications. From landfill liners to water management systems, geomembranes play a vital role in protecting the environment and ensuring the safety of engineering projects. As the demand for sustainable solutions continues to grow, the importance of geomembranes in engineering will only increase, making them a cornerstone of effective environmental management.