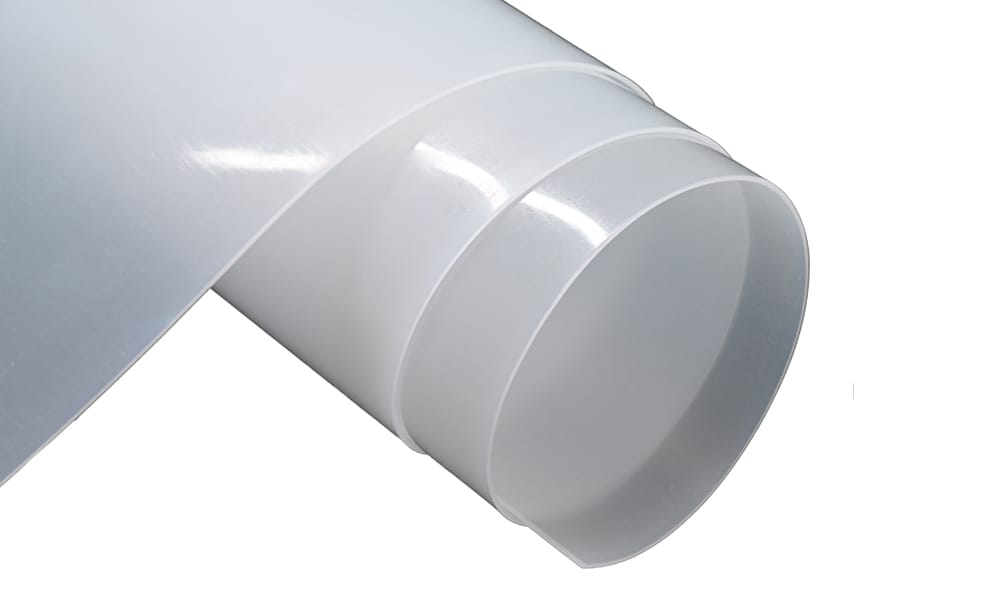

EVA geomembrane is a type of EVA sheet made from synthetic polymer materials combined with geotextile fabrics. Known for its versatility, Ethylene Vinyl Acetate (EVA) is widely recognized as one of the best materials for use across various industries, including transportation, aquaculture, water management, and landfills. Tinhy’s EVA geomembranes stand out for their exceptional impermeability, outstanding puncture resistance, remarkable flexibility, robust physical properties, and strong anti-corrosion capabilities. These features make them ideal for on-site construction projects, even under low-temperature conditions.

EVA geomembranes are extensively used in anti-seepage and waterproofing projects for tunnels, subways, water conservancy works, tailing dams, highways, solid waste landfills, and more.

Product Details:

EVA geomembranes are part of Tinhy’s Geomembrane series and are manufactured using polymeric materials, with anti-aging agents incorporated throughout the production process. This ensures that our EVA geomembranes perform effectively in anti-seepage and waterproofing projects, even under extreme temperature conditions. EVA, or ethylene-vinyl acetate copolymer, is known for its exceptional flexibility, excellent elasticity, adaptability to various environments, and strong bonding properties. Additionally, the mechanical performance of EVA materials surpasses that of conventional polyethylene.

EVA geomembranes offer outstanding physical properties, including excellent tensile strength, superior tear resistance, effective elongation, resistance to acids and alkalis, corrosion resistance, anti-aging durability, and reliable impermeability. For inspiration, you can explore our latest applications in aquaculture, landfills, and water management. If you’re considering implementing EVA geomembranes in your local anti-seepage or waterproofing projects, feel free to contact our sales team for inquiries and further assistance.

Specifications

| Item | Details | Unit | Standard | Test Frequency | ||||||

| Mechanical Properties | Thickness Degree | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 | |

| Density Data | g/cc | D1505/D792 | per formulation | 0.94 | ||||||

| Tensile Properties | ||||||||||

| Yield Strength | KN/m | D6693 | 10,000 kg | 11 | 15 | 22 | 29 | 44 | ||

| Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | ||||

| Yield Elongation | % | Type IV | 12 | 12 | 12 | 12 | 12 | |||

| Break Elongation | % | 700 | 700 | 700 | 700 | 700 | ||||

| Tear Resistance | N | D1004 | 10,000kg | 93 | 125 | 187 | 249 | 374 | ||

| Puncture Resistance | N | D4883 | 10,000kg | 120 | 160 | 240 | 320 | 480 | ||

| Stress Crack Resistance | hr. | D5397 | per GRI GM-10 | 300 hr. | ||||||

| Carbon black content | % | D4218 | 9,000kg | 2.0-3.0% | ||||||

| Carbon black dispersion | D5596 | 20,000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | |||||||

| Reference Properties | Oxidative Induction Time | |||||||||

| Standard OIT | min | D3895 | 90,000kg | 100 min | ||||||

| High-pressure OIT | D5885 | 90,000kg | 400 min | |||||||

| Oven Aging at 85°C retained after 90 days | % | D5721 | per formulation | 0.55 | ||||||

| Standard OIT | D3895 | 0.8 | ||||||||

| High-pressure OIT | D5885 | 0.8 | ||||||||

| UV Resistance | ||||||||||

| High-Pressure OIT – % retained after 1600 hrs | % | D5885 | per formulation | 0.5 | ||||||

| Roll Size | Roll Width | m | 7 | 7 | 7 | 7 | 7 | |||

| Roll Length | m | 280 | 210 | 140 | 105 | 70 | ||||

| Size stability | % | 0.02 |

Reviews

There are no reviews yet.