Geomembrane projects are significant in many areas like environmental protection, water resource development, and waste treatment. However, geomembrane projects generally need to overcome a series of challenges in weather, terrain conditions, etc. To address these challenges, careful planning, quality materials, and cooperation with reliable geomembrane suppliers are required.

Severe Weather Conditions and How to Deal With Them

Severe weather conditions are among the largest of problems to geomembrane works. Aggressive weather conditions can severely impact geomembrane performance. Geomembranes made under heat employing material such as HDPE would tend to get softer and contribute towards deformation as well as the weakening of material. Under cold weather, the material becomes brittle and more prone to cracking during installation or in service.

Rain and high humidity may also become problems. Moisture can prevent the geomembrine from bonding well to the substrate, reducing its effectiveness. Additionally, heavy rain can cause puddling of water at the site, slowing the work and potentially damaging geomembrane already installed.

To overcome these climatological hurdles, it is of the utmost significance that the right geomembrane product is selected. Geomembrane producers typically supply geomembranes with added temperature resistance.These specialized geomembranas hdpe are made to maintain physical properties within a wide temperature range. For example, some advanced geomembranas hdpe can withstand high temperature without significant softening and in low temperatures to be flexible.

During construction, closely monitor weather forecasting. Avoid performing installation operations during adverse weather conditions. In case of a rain forecast, take precautions such as covering the construction area with tarps to keep the substrate and geomembrane dry. This enables the geomembrane to be installed and bonded properly and to remain intact.

Challenging Terrain and Installation Problems

Complex terrain is also a prime obstacle for geomembrane works. Irregular surface, steep ground and stone terrain prevent smooth placement of geomembranes. In an irregular ground, geomembranes may not be laid flat, causing bubbles or wrinkles, which will affect their sealing ability of the geomembranes. Steep ground will increase the risk of sliding during construction or with time, and stone ground may perforate the geomembrane and cause leakage.

In order to address terrain problems, proper site preparation is necessary. Level the land as much as possible and clear out pointy objects before placing the geomembrane. In case of sloping ground, use the right anchoring systems from a reliable geomembrane supplier. The systems can be used to anchor the geomembrane and prevent it from sliding. Custom-designed anchoring solutions based on the specific needs of the project terrain are provided by some suppliers.

In rocky environments, a protection layer below the geomembrane should be implemented, i.e., a geotextile layer to act as a cushion that reduces punctures. The services of an installation team skilled in operating in challenging terrain also need to be hired. Their expertise and skills ensure that the geomembrane is correctly installed even in less-than-favorable conditions.

Partner with a Reliable Geomembrane Supplier to Ensure Quality

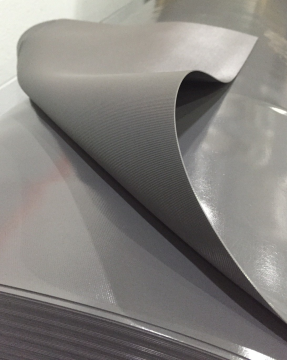

Choosing a reliable geomembrane supplier is the guarantee of success for any geomembrane project. Reliable suppliers not only provide quality geomembrane products (e.g., HDPE geomembranes), but also complete after-sales service and technical support. Reliable suppliers conduct strict quality control tests on their products, so that the geomembranes are of international standards and have superior sealing performance and durability.

They also have deep understanding of the needs of different projects and are able to recommend the most suited geomembrane products based on application conditions, environmental conditions, budget, etc. For example, for uses in highly corrosive environments, the suppliers are able to recommend HDPE geomembranes with high chemical resistance.

Moreover, a trusted geomembrane supplier can also provide valuable installation guidance. They can provide installation guides, take the installation team through on-site training, and provide advice on unforeseen site issues during construction. Such support ensures that the geomembrane is correctly installed, resulting in maximum efficiency and lifespan.

Long-term Maintenance and Monitoring Problem and Solutions

Even if the geomembrane project is successfully completed, its long-term monitoring and maintenance are still faced with ongoing challenges. Geomembranes can be undermined by soil settlement, root invasion, and chemical corrosion over the years, gradually compromising their integrity. Conventional manual inspection procedures are time consuming, labor-intensive, and do not detect certain concealed issues.

To remove these long-term maintenance problems, sophisticated monitoring equipment needs to be installed. For example, the use of a geomembrane leakage detection system by resistivity or infrared thermal imaging can detect possible points of leakage rapidly and effectively. Regular inspections with data analysis of monitoring results can detect problems at the early stage. At the same time, the geomembrane producers can supply maintenance techniques and suitable repair materials to restore and maintain the compromised areas in timely manner and extend the service lifespan of the geomembrane.

Conclusion

In summary, geomembrane projects are faced with a lot of problems related to weather, ground conditions, personnel operation, and long-term maintenance. All of these challenges can be easily overcome by employing quality HDPE geomembranes from reliable geomembrane manufacturers, preparing for every situation carefully, and employing advanced maintenance and monitoring methods. This results in successful geomembrane project execution and long-term performance of geomembrane systems. Geoseal is a professional manufacturer of high-quality geomembranes and has a technically mature after-sales service team to support you. We look forward to cooperating with you.