Geomembranes are used for anti-leakage and environmental protection in most engineering works such as landfills, water conservancy, and mining environmental protection. However, the quality of geomembranes used varies greatly, and knowing how to measure the quality of geomembranes is very key to the success and viability of the project. In this article, we will review several key points to help you judge the quality of geomembranes effectively.

Material Composition and Raw Materials

Types of Synthetic Materials

Geomembranes are predominantly produced from synthetic polymers, the most common of which include HDPE, LLDPE, and PVC.

HDPE geomembranes are resistant to chemicals, have high tensile strength and durability and therefore are suitable for aggressive environments such as landfills and mining.

LLDPE geomembranes are more flexible and easier to install and are generally used in applications where flexibility is required, such as small reservoir water tanks.

PVC geomembranes can be plasticizer-filled, and the quality would also depend on the nature and amount of the fillers. Low-quality plasticizers that are used in PVC geomembranes can eventually lead to brittleness, thereby lowering their working life.

In assessing quality, that the synthetic material utilized is known and meets the requirements of the specific project should be appreciated.

Raw Material Purity

Pure raw materials are employed to produce quality geomembranes. Impurities in the raw material can affect the performance of the geomembrane significantly. HDPE, for example, has its composition weakened by foreign debris or low-quality recycled content, which weakens its tensile strength as well as impermeability. Those companies that use 100% virgin raw materials have greater quality control and can provide higher-quality geomembranes. When assessing purity, you can ask for material certificates from the manufacturer that will indicate the origin and composition of raw materials.

Manufacturing Process and Workmanship

Extrusion Technology

The manufacturing process of geomembranes, especially extrusion technology, plays an extremely powerful impact on quality. Temperature, pressure and speed during the process of extrusion need to be strictly controlled. The polymer will degrade if the temperature is excessively high, and thus the mechanical properties of the geomembrane will be affected negatively; if the temperature is too low, the material will not be fully melted, so that the uneven thickness and weak points can result. Sophisticated production lines with automatic controlling systems may offer more stable quality. Certain advanced high-end producers, for example, use three-layer co-extrusion technology to produce geomembranes with better performance.

Weld Quality

Welds are usually the weak link of the geomembrane and must be good in bond strength and integrity. There are several different methods of making welds, including hot air welding, extrusion welding, and adhesive bonding. Hot air welding and extrusion welding are generally more uniform for thicker geomembranes because they have the ability to form a molecular bond. To test weld quality, examine whether the weld is flat, even, and gap- or hole-free. Top-notch weld tensile strength must be similar to the strength of the material of the geomembrane itself. In some cases, manufacturers will provide weld strength test reports to prove their workmanship.

Physical and Mechanical Properties

Tensile Strength and Elongation

Tensile strength is the geomembrane’s maximum stress it can withstand before it ruptures, while elongation measures how much the membrane can be stretched without rupturing. Both are essential quality measures for geomembranes. The ideal geomembrane must have sufficient tensile strength to withstand outer loads such as soil pressure and damage by mechanical forces during installation. For example, in landfill use, the geomembrane needs to endure the stress and potential movement of the refuse without failure. Similarly, adequate elongation allows the geomembrane to adjust to settlement of the ground or deformation without rupture. Geomembranes can be tested under tensile strength and elongation by standardized test procedure, e.g., ASTM D4885, to accurately measure these properties.

Permeability

The single most significant function of a geomembrane is the prevention of leakage of liquids and gases, and consequently low permeability is one of the most significant quality attributes. High-quality material and appropriate manufacturing processes make geomembranes very low in permeability. Permeability is most frequently measured by the permeability coefficient which indicates the rate at which a fluid will flow through a geomembrane under specified pressure conditions. The permeability of a geomembrane can be determined by lab testing, e.g., hydraulic conductivity testing. For critical applications such as hazardous waste landfills, ultra-low permeability geomembranes are required in order to provide long-term environmental security.

Appearance and Dimensions

Surface Quality

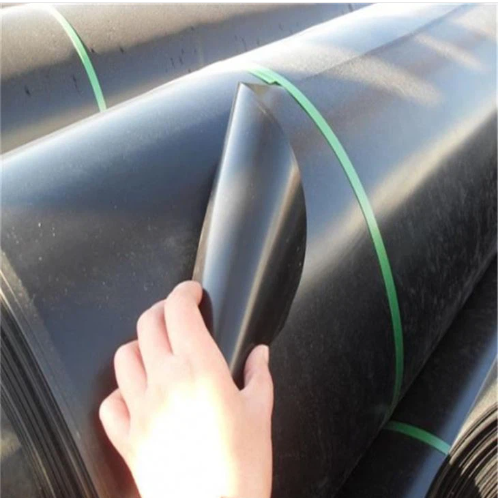

Inspecting the surface of a geomembrane is a simple and effective way of initially assessing its quality. The surface of a quality geomembrane should be level and plain with no perceivable flaw in the shape of bubbles, scratches or impurities. Bubbles may indicate improper extrusion or air mixing during manufacture and weaken the membrane; scratches or cuts will become stress concentration points and increase the risk of rupture. In addition, the color should be uniform. Inconsistent of color may indicate unevenness of raw material or manufacturing process.

Thickness and Dimensional Accuracy

Accurate thickness and dimensions are key to the performance of geomembranes. A geomembrane’s strength, durability, and impermeability rely on thickness, and variations from specified thickness can result in inconsistent membrane performance. For example, when the thickness is too thin in areas, it will not be adequate in preventing leakage. Dimensional accuracy is also required, especially in big projects where geomembranes are to be cut and installed with precision. The manufacturers should be able to provide accurate thickness measurement reports and manufacture the geomembrane the size required for the project.

Certifications and Quality Assurance

Industry Certifications

Quality producers typically have numerous industry certifications, which are good determinants of product quality. ISO 9001 (Quality Management Systems) and ISO 14001 (Environmental Management Systems) along with product-type certifications (e.g., ASTM certification for US geomembranes) are assurances that the producer has strict quality control measures in place and complies with international standards. In geomembrane search, having such certifications ensures that the product was rigorously tested and meets the intended quality level.

Quality Assurance Documents

In addition to certification, producers should be able to provide thorough quality assurance documents, including material test reports, production process documents, and product inspection reports. These can provide detailed information regarding the quality of the geomembrane from raw materials through final product inspection. For example, material test reports can specify the chemical makeup and physical properties of raw material.

Conclusion

Evaluation of the quality of geomembranes entails a comprehensive evaluation of the material composition, manufacturing process, physical and mechanical properties, appearance, and certification. Through extensive evaluation of all these, project managers, engineers, and procurement personnel can select high-quality geomembranes that are appropriate to the specific requirements of the project. This not only ensures effortless execution of the project but also environmental safety over time and preservation of infrastructure.

Geoseal is a hot sale geomembrane supplier that can provide you with professional service and consulting and look forward to being your business partner.