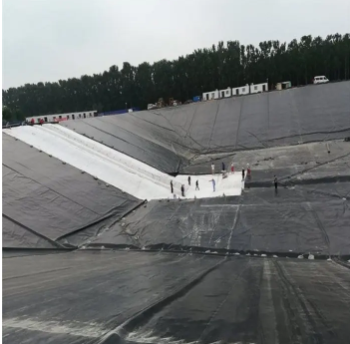

Geomembrane installation on slopes is one of the most significant operations in most engineering works, like landfills, reservoirs, and irrigation system construction. Slope geomembranes installed correctly can be an effective barrier against soil erosion minimization, seepage of liquids, and pollution hazards to the surrounding environment. The slope topography does exist with special techniques and maximum care in consideration of its inherent difficult nature. The article will provide you with a step-by-step guide to the entire process of geomembrane installation on slopes.

Pre-installation Preparations

Site Inspection and Preparation

The first thing is to conduct a comprehensive site survey. Check the slope carefully for potential hazards that could damage the geomembrane, such as rocky edges, bare tree roots, or uneven surfaces. Use the appropriate tools to dig out all debris, loose soil, and vegetation. On rock slopes, use a grinder to deboss rough edges and repair holes and fissures with a soil and mortar mixture. The secret to an effective geomembrane installation is a well-prepared and flat slope surface that will ensure good adhesion and long-term durability.

Material Selection and Quality Control

The correct geomembrane material needs to be selected and decided upon based on the specific requirements of the project. The most widely used materials are HDPE, LDPE, and PVC. The different materials possess different properties regarding chemical resistance, impact resistance, and flexibility. As an example, the HDPE geomembrane is used in landfill infrastructure construction due to its chemical resistance with suitable tensile strength, along with being resistant to harsh environmental conditions. Inspect the geomembrane roll for defects such as holes, tears, or non-uniform thickness before installation to ensure that the selected geomembrane meets all the quality standards for it.

Installation Steps

Geomembrane Deployment and Positioning

Installation begins with the installation of the geomembrane at the top of the slope. Use a tensioner to control the rate of deployment and keep the geomembrane flat and wrinkle-free. Position the geomembrane accurately, with a proper overlap of 10 – 20 cm between neighboring panels as per project requirements. Align the geomembrane precisely along the slope to fully cover the entire slope.

Geomembrane Welding

Welding is a critical process in the installation. Two main ways of welding are hot air welding and extrusion welding. Hot air welding may be used on thinner geomembranes, where hot air fuses the surface to form bonding. extrusion welding is typically used on thicker materials, where plastic is melted out to form a solid joint. Thoroughly clean the welding surface of dirt, dust and moisture prior to welding. Preheat the welding temperature and speed according to the thickness of the geomembrane and material. After welding is completed, quality tests such as air pressure test and peel test are performed in order to measure the strength of the weld. Weak or defective welds need to be repaired at once.

Anchoring and Fixing of Geomembranes

In order to prevent the geomembrane from slipping along the slope, it must be anchored. A trench of sufficient depth and width is dug at the top of the slope, and the geomembrane is placed in the trench and backfilled with concrete or soil. Steel bars or plastic nails are inserted at regular intervals along the slope to anchor the geomembrane on the slope surface. For more risky slopes, extra measures of reinforcement might be needed, including the installation of a geotextile.

Key Considerations During Installation

Installation Under Weather Conditions

Weather affects installation severely. Do not install geomembranes on rainy, windy, or extreme weather conditions. Rain causes the slopes to become slippery and influences the adhesion of geomembranes; wind can wrinkle geomembranes; extreme temperatures can influence welding quality. Install under stable, mild weather conditions.

Strict Quality Control

It is important to maintain rigorous quality control throughout the process of installation. Check from time to time throughout the process of installation for flatness of the geomembrane, weld, and anchoring effect. Document detailed inspection results and resolve any quality issues on an immediate basis. Conduct a general quality check before the completion of project ensure that the installation meets all design and quality standards.

Geoseal – Your Trusted Geomembrane Installation Expert

Geoseal has extensive experience and expertise in the installation of slope geomembranes. Our highly skilled team is well experienced in the latest installation methods and closely adheres to industry standards. We provide a full range of services that include site assessment, materials selection, construction and installation, and post-sales support.

We insist on the employment of good-quality geomembrane material along with advanced installation equipment. Strict quality inspections are carried out to guarantee that every project we execute has the best quality and durability standards. Be the project small or large, from a minor irrigation project to a massive landfill project, we are able to provide customized solutions according to your needs.

Choosing Geoseal, you can rest assured that your slope geomembrane installation project will be professionally, efficiently and safely completed. Contact us today to learn more about how we operate and start a reliable geomembrane installation project.

Conclusion

Shortly, geomembrane installation on slope is a complex process of pre-designing, precise execution, and strict quality control. Every step from the preparation of site to the final anchorage plays its role in making the geomembrane system survive for a long time and maintain its integrity. With a careful follow-through of the steps and precautions provided in this article, problems can be prevented and a top quality installation can be achieved.

Geoseal is a wholesale geomembrane supplier. Choosing us is choosing the easy, quality geomembrane installation solution for your slope project. Looking forward to hearing from you.