Geomembranes are the key component in the majority of engineering works as the key barrier to prevent liquids from leaking and leading to environmental pollution. Long-term use exposes geomembranes to a variety of durability issues, the most visible of which include material aging and puncture risk.

Material Aging: a Possible Hazard to Geomembranes

Aging of the material is one of the most important durability problems faced by geomembranes. Geomembranes are subjected to a series of environmental conditions during their lifespan that promote aging. Ultraviolet solar radiation is one of the predominant causes of this. Since geomembranes, especially those which are placed outdoors such as landfill caps, are exposed to UV radiation all the time, the polymer chains of the material break down, leading to a decrease in mechanical strength and an increase in brittleness.

Oxidation is also a cause of aging. The oxygen in the atmosphere oxidizes geomembrane polymer materials, gradually altering their chemical structure. Temperatures that are high, whether hot or cold, also cause repeated expansion and contraction of the material, which generates microcracking. Microcracks continue to grow and also reduce the strength of the integrity of the geomembrane liner and its efficiency as a barrier.

For example, in some water reservoir schemes, geomembranes originally installed to provide water leakage have begun to age when exposed to sunlight and temperature fluctuations for decades. There were minor cracks and loss of flexibility exhibited, which may cause water seepage as well as environmental contamination if not attended to.

Puncture Risk: Violation of the Integrity of Geomembrane Liners

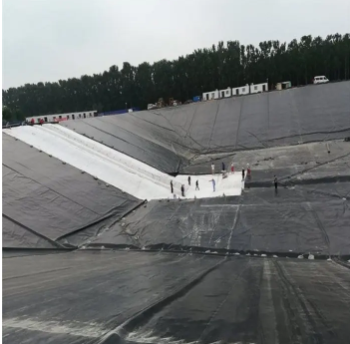

Puncture is the second primary durability challenge that geomembranes face. Geomembrane liners are typically placed on uneven ground or wherever the presence of sharp items exists. Geomembranes are highly likely to be punctured during the time of installation if the ground or substrate below contains rocks, roots of trees, or hard objects. Minor punctures can grow into large breaches over the period of time due to stress and strain under usage.

In landfilling, geomembranes are punctured by sharp-waste fragments such as metal fragments or glass. These can move through and allow channels for the leachate to pass through. Underwater branches or fish movements in reservoir or farm ponds may also pierce geomembrane liners. Once punctured, the protective capacity of the geomembrane will significantly decrease, and it will no longer be able to effectively isolate the contents from the surroundings.

Solutions to Enhance Geomembrane Strength

For the solution of material durability problem of puncture and aging, many solutions can be implemented. It is the geomembrane suppliers who play an important role in supplying high-quality geomembranes with greater durability properties.

One of the ways is to use geomembranes with anti – UV additives. Anti-UV additives absorb or reflect UV light and hence do not allow the polymer material to degrade. Certain geomembrane suppliers now offer products with advanced formulations that are resistant to UV and can extend the service life of geomembranes in outdoor applications by several years. Additionally, the use of antioxidants incorporated into geomembrane materials can slow down the oxidation process and maintain material’s mechanical properties for a considerable time.

In terms of preventing punctures, proper site preparation before geomembrane placement is necessary. These include the removal of sharp objects from the installation area, ground surface grading, and the provision of a protective layer, i.e., geotextiles, between the soil and the geomembrane liner. Geomembrane producers also offer geomembranes with some thickness and strength in specific puncture-exposed areas to make the overall puncture resistance of the liner more effective.

In addition, regular inspection and maintenance are very important for the early detection of potential aging or puncture issues. In some large projects, advanced monitoring techniques such as resistivity measurements can be used to detect even minute defects in the geomembrane. Once a problem is detected, repair or replacement measures can be taken in good time to prevent further damage.

Conclusion

Material aging and punctures pose a major danger to geomembrane long-term performance. But efficient countermeasures like the use of high-performance geomembrane products offered by geomembrane manufacturers, proper installation procedure, and proper maintenance can be implemented in a way to increase geomembrane service life and efficiency. By overcoming these issues, geomembranes can continue to play an important function in engineering applications. Geoseal is a geomembrane manufacturer and looks forward to cooperating with you.